-

response@eaglescales.com -

+91-9909964599, +91-9712972557, +91-9909964590 - Send SMS

- Send Email

- GST No. 24AAWPP5396A1ZB

Weigh in Motion System

Leading Manufacturers, Exporters, Wholesaler and Retailer of Truck Weigh In Motion System, Rail In Motion Weighbridge and Portable Axle Weigh Pad from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Voltage | 110V, 220V |

| Weight (Kg) | 100-1000kg |

| Automatic Grade | Semi Automatic |

| Power | 1-5kw, 10-15kw |

| Driven Type | Electric |

| Warranty | 1year |

Preferred Buyer From

| Location | Anywhere in India |

Eagle - Wim For Toll Plaza,Toll Roads & Bridge :

- The Vehicle weight , not the numbeer of axles,determines wear and tear of roads.Toll authorities now use weight-based tolling,which relies on weigh-in-motion technology to determine the proper toll classification while keeping the traffic moving.

- Its rigid construction significantly improves scale reliability in heavy-duty operation and helps to archieve precise positioning into the road during installation thus redusing the installation costs.The Weighbridge is connected to traffic lights and signals horn to control vehicle movement.Video camera for vehicle detection and vehicle image capturing can be delivered as optional equipment.

- Close Coupled Axles : The platform has been specifically designed to take all combinations of axles. Single axles, tandem and tri-axle combinations are easily weighed because the electronics can capture the weights of every axle individually. Close coupled axles with spring or air suspension are no problem to the weighbridge which will take individual axles of up to 30 Ton each

Key Benefits :

- Instant check for road legal weight

- Fully unattended weighing operation

- Weighs hundreds of vehicle daily

- Daily reporting measures vehicle productivity

- Automatic recording of weight and images of vehicle

- Gross weight,axle weights,numbers of axles can be recorded

- Data record can be stored for stored for future use or can be sent via LAN or Internet to the Server

Quality :

- Law Enforcement - A range of indicators and computer software is available for the EAGLE Axle which allow authorities to choose the best system for their enforcement needs. The Axle is particularly suited to where compliance with legislation is important as ‘overspeed’ weights are automatically detected so that vehicles cannot be presented with incorrect weighing tickets. The policy of EAGLE is to produce only top quality products incorporating the latest technological advances. Particular emphasis is placed on product reliability and durability and so the company undertakes all its own design and manufacture in order to maintain the essential high level of quality control.

- Dynamic Weighing - In-motion (dynamic) weighing is an established feature of axle weighing and was originally developed by EAGLE in the early 1991s. It is the basis of the Single Axle system and today with modern, state of the art electronic circuits it provides the highest accuracy for weighing individual axles. As a vehicle drives over the weighbridge in low gear the axles are automatically recorded on the move. The electronics calculates the actual weight of each axle as it passes over the platform and immediately displays the weight. Automatic operation of the weighbridge allows a driver to weigh without the need for a specialist operator to be present. A unique electronic zeroing system ensures that the correct weight is achieved for each axle and that zero adjustment between weighing is not required.

Process : The W.I.M processor is the heart of the weighing equipment. The signals from the weigh platform are connected to the W.I.M processor. A high speed processor is used to process the data and to respond to the instructions from the main computer. The output of the W.I.M processor is connected to the computer. The weighing software from the computer will interact with W.I.M processor and the complete data of the vehicles is recognized.

The Following data of the vehicles is generated :

- The total weight of the vehicles

- Each individual axle weight

- Numbers of axle of the vehicle

- Data and time of vehicle passed on the weigh in motion scale

- Images of the vehicle (if cameras are used)

- The vehicle number plate can also be recorded along with the weight data

- Number of vehicles passed on the weigh in motion scale Speed of the Vehicle

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Voltage | 220V |

| Weight (Kg) | 100-1000kg |

| Automatic Grade | Semi Automatic |

| Power | 1-5kw |

| Driven Type | Electric |

| Warranty | 2years |

Preferred Buyer From

| Location | Anywhere in India |

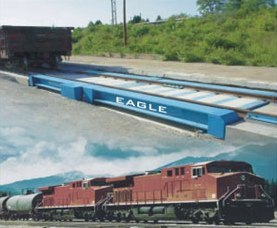

We provide superior quality rail weighing systems, automatic weighing systems that are based on latest technology. Our rail in motion weighing systems is available in customized mode to meet the exact demands of our clients.

Our wide array of rail in motion weighing systems comprises of the following :

- Eagle Combo rail in motion weiging system designed in accordance with the worldwide requirement Railways/RDSO.

- The system design is very simple yet powerful, allow you to install the system in short span even at a very narrow curved line.

- The system has been designed with new and simple algorithm to deduct complex engine and wagon’s track pattern.

- The improved Rail Sensor design allow our combo rail fit for even short span of Straight Line requirement even less than 45Mts .

- The user has get wide choice for the software, inter connectivity vie Ethernet, GMS, USB. The system can be simple pit and Pitless design.

Specification :

- Weighing Capacity - 120 T for individual Wagon

- Type of Wagon - All types of standard Wagons of Indian Rly.

- Type of Weighing - Axle

- No. of Axles - 2, 4 axles wagons

- Axle: Load - 45 Ton (Maximum)

- Weighing Speed - 15 KM/Hr.

- Direction of Weighment - Bi Direction

- Load Sensor Type - Strain gauge, hermitically sealed

- No of strain gauges per weigh Rail - 2

- Surge protection - In built

- Safe over load withstand capacity - 150% rated capacity

- Calibration - Automatic

- Increment - Selectable 20/50/100 Kg

- Accuracy - (+) / (-) 0.5% for wagon (+) / (-) 0.2% for complete rake

- Power Supply - 230 V, +/- 10% single Phase 50 Hz

Protable weigh pad :

- Fix on embedded - rail mounted sensor with hermetically sealed

- Pit / Pitless design option under single roof

- High speed and High accuracy

- Automatic correction of gain & zero

- Automatic Identification of Wagon and Engine

- Automatic Direction selection

- Auto Roll back up to 65000 wheels

- Direct print out of Rake information

- RDSO approved.

- Approved under CLASS 0.2 As per OIML/LM

- Advanced over speed indicator

- Modular design for Silo and RLS loading

- High mv/v output with reduced SNR

- Inbuilt surge and lightning arrester

- Well built and maintenance free

- Weather proof design

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Input/output Resistance | 560 ohms +/- 50 ohms |

| Rated capacity | up to 20 ton per pad @ 20 lb graduations |

| Material | High strength aluminum alloy |

| Static Accuracy | 0.25% full scale or better |

| Dynamic Accuracy | +/- 1% of full scale with leveling track (See Weigh in Motion) |

| Overload Capacity | 200% full scale |

| Stability | 0.5% full scale/year |

| Ground level Requirement | <5mm within 0-4m |

| Weight | 52 lbs including ramps, 42 lbs without ramps |

| Operating Temperature range | -10 to +55 deg C |

| Output | 0.6 to 1.0 mV/V |

| Excitation | 5 to 24 VDC |

Preferred Buyer From

| Location | Anywhere in India |

Single Axle Weighbridge :

- Axle weighbridges are a very good choice for Mines and Factories, where installations are required to be quick. Shifting axle weighbridge can be done quickly and needs only a small pickup truck for transportation.

- Axle weigh bridges are very cost effective solution, the user benefits from the low equipment cost, low cost of civil work & installation and hence rapid recovery on investment.

- Civil work takes only 3 to 4 days time and the installation can be done in just one day. With its many advantages and cost benefits, axle weighbridge is highly rewarding solution with no compromise.

Features :

- Quick delivery and installation

- Low Cost

- Very low cost on civil work

- Installation in one day

- Powerful software (AXSOFT) which gives total control and accountability

- IP-68 protection for load cells

- System fully protected from lightening

- Rugged instrumentation to give seamless performance

- Capacity up to 60 Ton